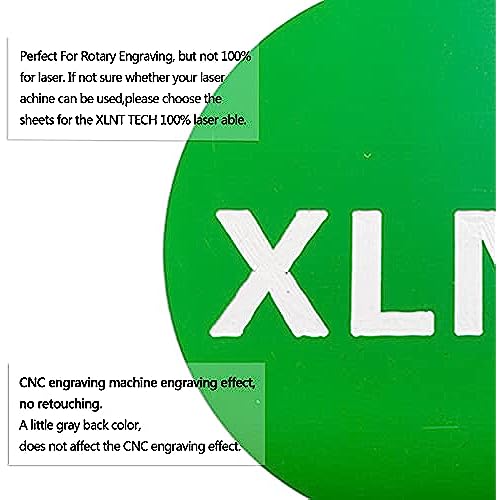

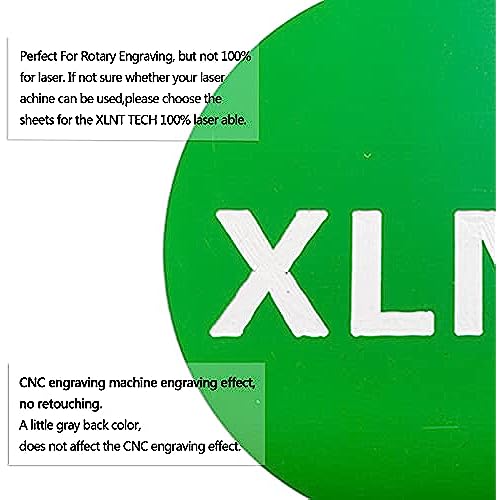

XLNT TECH Engraving Double Color Sheet (7 x 11“ x .040”, 12 Pieces & 12 Colors) for Interior Signs, Badges.

-

Trinidad Sanchez

> 3 dayNot laserable

-

JLLDesigns

> 3 dayused on a co2 laser engraving machine. received today and had a great trial run on this product. much cheaper option than other suppliers.

-

Robert Adams

> 3 dayAll the colors show a color layer, a white layer and then another color layer. They have a very very thin color layer, then a thick .039 white layer. I feel that the ad by the depicted display is out and out wrong. I will use them but, they are not what I ordered per ad as shown.

-

Jaydon VonRueden MD

14-04-2025Great material, but mine came at 0.043” instead of advertised 0.060”. Measure and setup CNC machine properly.

-

mountaingeek

Greater than one weekFirst of all, laser cutting ABS does not produce Chlorine gas like burning PCV does. So never cut PVC with a laser. That being said, burning ABS can produce hydrogen cyanide gas. How much? Difficult to say, but hydrogen cyanide gas is produced by burning many things, including cigarettes. Lasering wood also produces many toxic compounds. So no matter what you engrave or cut on a laser good ventilation and avoiding inhaling any of the fumes is necessary. Now to this particular material. Finding the right setting for your laser may take some significant trial and error. I have a Boss 1630 105W CO2 laser and ran at least 30 combinations of speed, power, air and painters tape before getting so reasonable results. The pictures are from a 6 inch wide placard I made. From 12 inches away the engraving is smooth and clean. If examined closely, you can see ridges in the cut from the laser scanning. The settings I settled on are 400 mm/sec at 35% power for the fill and 35 mm/sec at 60% power for the outline cut. Air was on and the surface was covered with painters tape to prevent smoke staining around the edges of the engraving and cut. I tried leaving the top film on instead of the painters tape but the result were not as good. The engraving was done at 300lpi. Lower lpi increased the ridges in the engraving. My only real complaint is that the white bottom layer is not very white - more of a grey.

-

astrophotographer

> 3 dayI bought the product to engrave. I did a test engrave Nd tbought the white part slightly burned during the engraving leaving a darker color than white. I then checked the back of it and say it was a grey color and not white. I returned it and ordered another thinking maybe it was a mistake and i still got red and grey instead of red and white

-

Sigmund Mann DVM

> 3 dayWe used our 50W laser engraver at the lowest setting, and the results were terrible. The colored film bubbled at the edges and flaked off, and the melt patterns of the ABS are also bad. There are no guidelines as to what power settings should be used, so maybe a 50W is just too much. Im requesting a refund, and I do not recommend these for laser-engraving.

-

kmadison

> 3 dayThin material - but with a few practice runs at various settings on my CNC - I got perfect results with a 1/16 down cut bit. Easy to cut material to size on table saw.

-

Spence Butler

> 3 dayProduct is better then i expected

-

Kiwi

> 3 dayThese worked great for the electrical project we had. Used them with a laser and exceeded my expectation.